Add to Cart

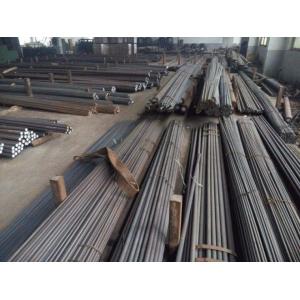

321 Stainless Steel Round Bar Diameter 2mm 3mm 6mm Metal Rods

| Product name | steel round bar | |

| Size | O.D | 8-480mm |

| Length | 1-12m | |

| Standard | AISI,ASTM,GB,DIN,BS,JIS | |

| Grade | 12Cr1MoV Cr5Mo 15CrMo 30CrMo 40CrMo 20SiMn 12Cr1MoVG 15CrMoG 42CrMo 20G | |

| Inspection | X-ray inspection, manual ultrasopic inspection,surface inspection,hydraulic testing | |

| Technique | Hot Rolled | |

| Section Shape | Round | |

| Main Market | Southeast Asia, Middle East, Australia,USA,South America,Africa | |

| Productivity | 5000 Tons/month | |

| Packing | Standard bundle package Beveled end or as per request | |

| Surface Treatment | Black Painted, PE Coated, Galvanized or Customized all available | |

| Date of Delivery | According to The Specifications And the Quantities Of Each Contract, Time Start To Begin When We confirm the Date of the Earnest or L/C | |

| Method of Payment | T/T L/C West Union | |

| Method Of Delivery | Terms According To the <INCOTERMS 2000> for International Trading | |

| Remarks | 1.Payment Terms T/T, L/C,West Union | |

| 2.Trade Term:FOB/CFR/CIF | ||

| 3.Minimum Quantity of Order: 2 Tons | ||

| 4.Delivery Time:7-15 days after receipt of deposit | ||

Round steel is a solid strip of steel with a circular cross section. Its specifications are expressed in millimeters of diameter, such as "50" refers to the diameter of 50 millimeters of round steel. Round steel is divided into hot rolling, forging and cold drawing. Hot rolled round steel is 5.5-250mm in size. Most of the small round steel of 5.5-25mm are supplied in straight bundles, which are commonly used as reinforcing bars, bolts and various mechanical parts. Round steel larger than 25 mm, mainly used in the manufacture of mechanical parts or as seamless steel billet.

Classification by process

Round steel is divided into hot rolling, forging and cold drawing. Hot rolled round steel is 5.5-250mm in size. Among them: 5.5-25mm small round steel is mostly supplied in straight bundles, commonly used as reinforcement, bolts and various mechanical parts; Round steel larger than 25 mm, mainly used for manufacturing mechanical parts, seamless steel tube billet, etc.

Classified by chemical composition

Carbon steel can be divided into low carbon steel, medium carbon steel and high carbon steel according to chemical composition (i.e. by carbon content).

(1) low carbon steel

Also known as mild steel, carbon content from 0.10% to 0.30% low carbon steel is easy to accept all kinds of processing such as forging, welding and cutting, often used in the manufacture of chains, rivets, bolts, shafts and so on.

(2) the medium carbon steel

Carbon steel 0.25% to 0.60% carbon. There are killed steel, semi-killed steel, boiling steel and other products. In addition to carbon, it can also contain a small amount of manganese (0.70% ~ 1.20%). According to product quality, it is divided into ordinary carbon structural steel and high quality carbon structural steel. Good hot working and cutting performance, poor welding performance. The strength and hardness are higher than low carbon steel, while the plasticity and toughness are lower than low carbon steel. Without heat treatment, directly use hot rolled material, cold drawn material, can also be used after heat treatment. The quenched and tempered medium carbon steel has good comprehensive mechanical properties. The highest hardness that can be achieved is about HRC55(HB538) and σb is 600 ~ 1100MPa. So in a variety of uses of moderate strength level, medium carbon steel is the most widely used, in addition to as a building material, but also a large number of used in the manufacture of various mechanical parts.

(3) high carbon steel

Often called tool steels, with carbon content from 0.60% to 1.70%, can be hardened and tempered. Hammers, crowbars, etc. are made of 0.75% carbon steel; Cutting tools such as drills, taps, reamers, etc. are made from 0.90% to 1.00% carbon steel.